Choosing the right safety valves for your applications can be a daunting task. Experts like Dr. Emily Carter, a leading authority in pressure relief systems, emphasize the importance of thorough selection. She once stated, "The right safety valves can save lives and equipment." This highlights the critical role these components play in various industries.

Understanding the specific requirements of your system is vital. Safety valves must match the operating conditions and media. Many overlook the unique needs of their applications, resulting in poor choices. Failure to select appropriate safety valves can lead to catastrophic events.

Consider factors such as pressure ratings and materials. Whether in oil, gas, or chemical industries, each application demands specific attributes. Quality and adherence to industry standards are non-negotiable. Often, companies prioritize cost over safety, which can lead to reflection on their long-term impact. Properly chosen safety valves can prevent costly downtime and enhance operational safety.

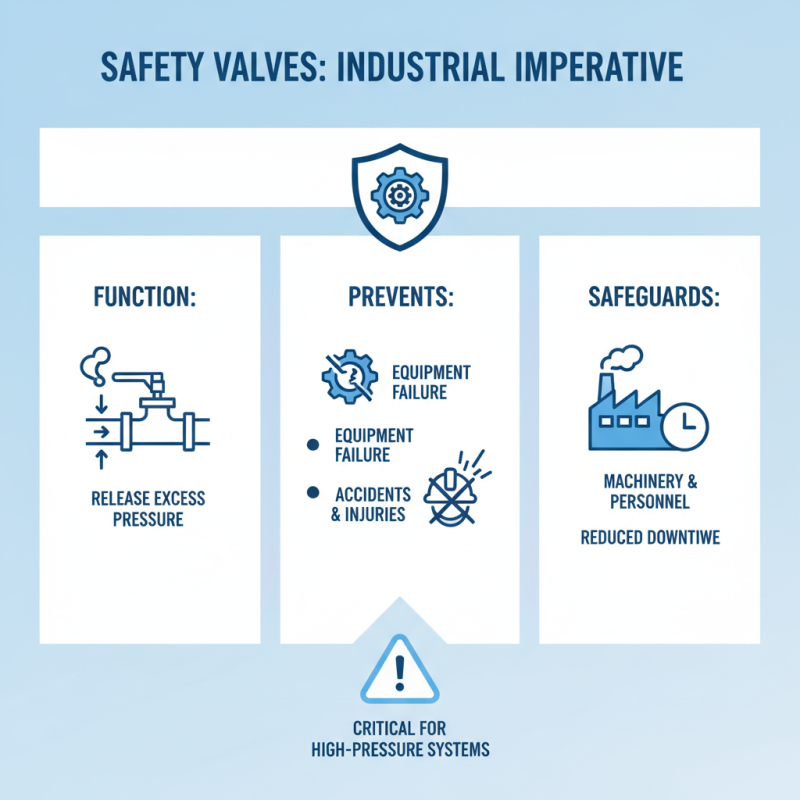

Safety valves play a critical role in industrial applications. They prevent equipment failure by releasing excess pressure. This function safeguards both machinery and workers in high-pressure environments. Without proper safety valves, systems can become hazardous. Equipment failure can lead to accidents, injuries, or costly downtime.

Choosing the right safety valve is not always straightforward. There are many factors to consider: pressure rating, size, and the medium being handled. Each application has unique requirements. A mismatch can result in insufficient protection. Sometimes, industries overlook these details, impacting overall safety.

Regular maintenance is also essential. Even the best valves require checks and adjustments to function correctly. Ignoring signs of wear can lead to failure. Monitoring performance ensures that safety remains a priority. Reflecting on safety practices can help improve decisions going forward.

Safety valves play a crucial role in various applications. They are designed to protect systems from overpressure. Different types of safety valves serve distinct functions based on the medium and environment.

There are various safety valves to choose from. The most common types include spring-loaded valves, pilot-operated valves, and balanced bellows valves. Spring-loaded valves are simple. They open when pressure exceeds a set limit. Pilot-operated valves, however, offer more precision. They use system pressure to control the discharge, making them suitable for high-pressure contexts.

In industrial settings, choosing the right valve is complex. Each application has unique requirements. Issues like temperature, pressure, and medium type all matter. Some valves may work poorly under certain conditions. A mismatch can lead to leaks or system failures. It's essential to consider these factors carefully. Observing how different valve types perform can lead to better decisions. Understanding these nuances helps in making the right choice for safety.

Choosing the right safety valve for your application requires careful consideration of operating conditions. A study by the American Society of Mechanical Engineers (ASME) suggests that over 50% of equipment failures stem from improper safety valve selection. Understanding the pressure, temperature, and fluid characteristics is crucial. This information drives the selection process and helps prevent costly downtimes.

Operating conditions, such as maximum allowable working pressure (MAWP), play a significant role. A wrong specification can lead to catastrophic failures. For instance, if a safety valve is set too high, it may not activate, risking equipment damage. Conversely, if set too low, it may trigger frequent unnecessary releases.

Material compatibility also factors in. Fluid properties can cause corrosion or erosion of valve components. According to industry reports, approximately 30% of failures are linked to material issues. Operators might overlook this but should analyze the fluid’s chemical makeup. Assessing the environment helps in choosing a valve that withstands specific conditions. This detailed evaluation cannot be neglected. Balancing all these variables is essential for optimal safety.

When selecting safety valves, material compatibility is crucial. It directly influences both durability and performance. Research indicates that improper material selection can lead to significant failures. In fact, about 30% of industrial valve failures stem from material issues.

Corrosion resistance is a primary concern. For instance, stainless steel suits many applications, but not all environments. In acidic conditions, other materials might perform better. A mismatch can quickly lead to leaks or valve failure. Thus, manufacturers recommend stress testing to ensure proper material usage.

Temperature ranges also play a role. Some materials can warp or degrade under extreme heat. A study published by the Journal of Pressure Vessel Technology showed that nearly 25% of valves fail due to thermal stresses. Users must consider these factors meticulously. It's not just about initial cost; long-term reliability often saves money. Each application varies, demanding careful evaluation.

When selecting safety valves, regulatory compliance is crucial. Different industries have specific standards. Familiarizing yourself with these can prevent future issues. Check local regulations and industry-specific guidelines to ensure adherence.

Consider the application environment. Is it high-pressure or corrosive? Different materials and designs meet various requirements. Each application may need a unique approach. Reflect on your choices. Have you evaluated all requirements thoroughly?

Seek guidance from experts if needed. Their insights can highlight overlooked factors. Sometimes, immediate solutions seem perfect, but they may not comply later. Take your time to analyze. Compliance can safeguard against liabilities down the line. Focus on selecting the right safety valve that aligns with both operational needs and regulatory expectations.

| Application Area | Type of Safety Valve | Pressure Rating (psig) | Material | Standards Compliance |

|---|---|---|---|---|

| Oil & Gas | Spring Loaded | 750 | Stainless Steel | ASME VIII, API 520 |

| Food Processing | Diaphragm | 150 | Hastelloy | FDA, USDA |

| Chemical Processing | Pilot Operated | 300 | Carbon Steel | ASME, CE |

| Power Generation | Dead Weight | 900 | Bronze | ISO 4126, ASME |

| Pharmaceuticals | Spring Loaded | 200 | 316L Stainless Steel | CGMP, FDA |

© Copyright 2025 | LittleFirefighter.com | All Rights Reserved | 1EZ Creative: Orange County Web Design

Fusce ut ipsum tincidunt, porta nisl sollicitudin, vulputate nunc. Cras commodo leo ac nunc convallis ets efficitur.

12345 North Main Street,

New York, NY 555555

1.800.555.6789

sale@vibrotools.com