The gasoline shut off valve is a crucial component in fuel delivery systems. It regulates the flow of gasoline, ensuring safety and efficiency in vehicles and machinery. According to industry reports, approximately 40% of fuel management issues are linked to valve malfunctions. This highlights the importance of understanding how these valves work.

These devices can prevent spills and leaks, which are significant environmental concerns. A malfunction can lead to fuel wastage, posing both safety risks and financial losses. In fact, the National Research Council estimated that improper fuel management costs the automotive industry billions each year.

While the technology is reliable, not all gasoline shut off valves are created equal. Some models may fail under pressure or have limited durability. Enhancements in design and materials are needed to address these weaknesses. Awareness of these issues can help users select better products and improve their systems' overall performance.

A gasoline shut-off valve is a crucial component in fuel systems. It controls the flow of gasoline, ensuring safety and efficiency. This valve is typically found in vehicles, generators, and small engines. When activated, it allows fuel to flow; when closed, it stops the flow completely.

Understanding its function can seem complex. The valve uses a simple mechanism. Often, it's operated manually or automatically. A lever or an electrical signal can trigger it. Many people overlook this device until it fails. A malfunction can lead to fuel leaks or engine issues. Regular maintenance is sometimes ignored, but it’s essential for safe operation.

In practice, users might forget about the shut-off valve's role. They might not realize its importance until an emergency arises. This can create a learning moment. Being proactive in checking this valve can prevent future problems. An informed user can appreciate their vehicle's overall performance more deeply.

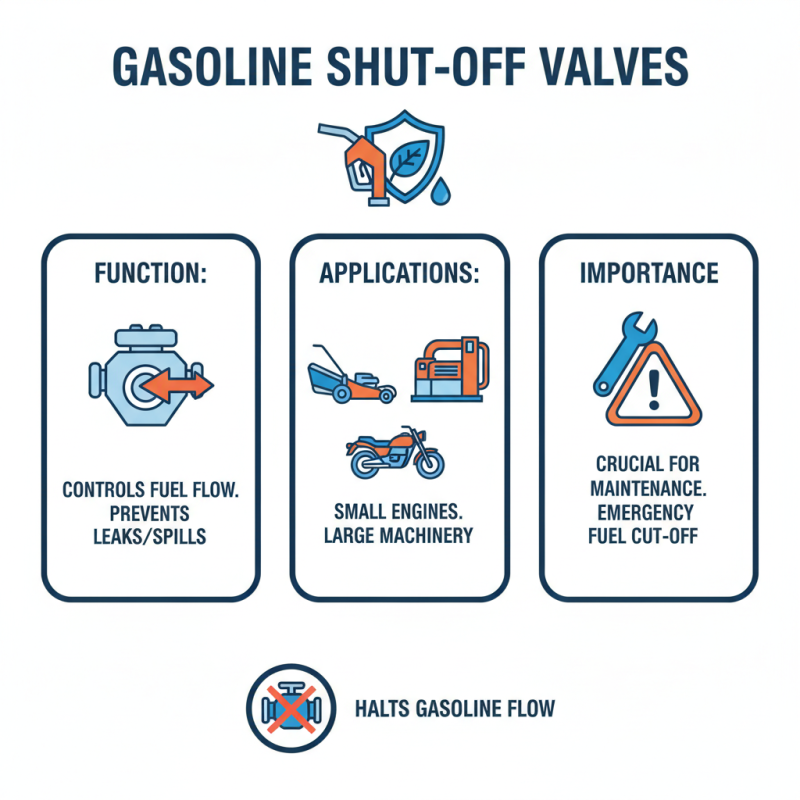

Gasoline shut off valves serve a crucial function in controlling fuel flow. They are commonly used in various applications, from small engines to large machinery. These valves help prevent leaks and spills, which can lead to environmental hazards. When a shut off valve is engaged, it halts the flow of gasoline. This function is vital during maintenance or emergencies.

Their importance is highlighted in areas where safety is paramount. Any malfunction can pose risks to both people and the environment. A simple oversight can lead to fuel leakage, which may cause fires or environmental contamination. Regular checks and maintenance are necessary to ensure these valves function properly. Sometimes, individuals may forget to inspect these components. This negligence can lead to costly consequences.

While gasoline shut off valves are essential as a safety measure, they also require proper installation and handling. Mistakes can occur, and reflection on past errors is important. Understanding how these valves work can prevent future issues. Education on their use can empower individuals to make safer choices.

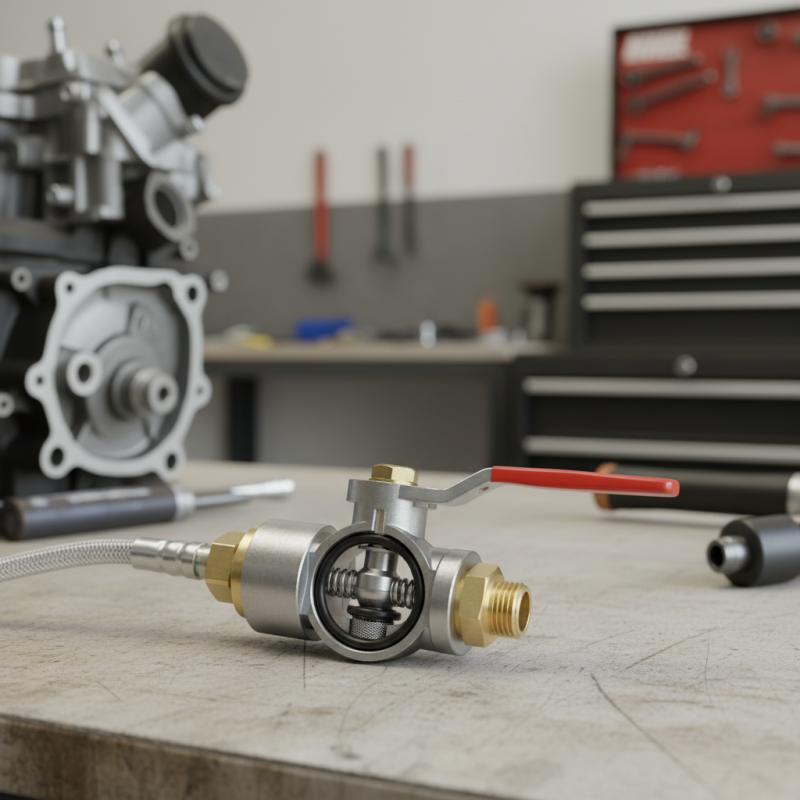

A gasoline shut-off valve plays a crucial role in fluid systems. It prevents fuel leakage, enhancing safety. Mechanics of the valve are quite fascinating. When the ignition is turned on, the valve opens, allowing gasoline to flow. Conversely, when the engine shuts off, the valve closes tightly, blocking the fuel line.

Operating mechanically involves a simple yet effective design. A spring-loaded mechanism usually controls the opening and closing. This ensures a fast response to changes in pressure, making it reliable in emergencies. According to industry reports, well-functioning shut-off valves can reduce fuel spills by over 50%. That's significant for both safety and cost.

Tips: Regular maintenance is key. Inspect valves for wear and tear regularly. Even minor leaks can indicate a need for repair. Ensure the mechanics are free of debris. Proper cleaning can prevent malfunctioning. Trustworthy references suggest monthly checks for optimal performance, especially before long trips. Always prioritize safety in fuel management practices.

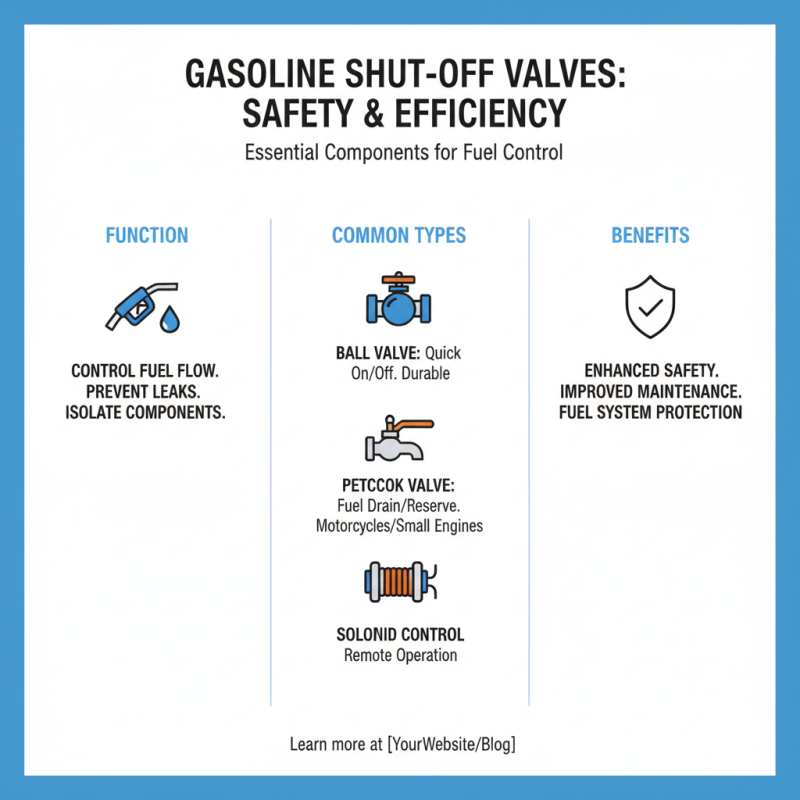

Gasoline shut off valves are essential components in various applications. They help control the flow of gasoline safely. Understanding the common types of these valves can enhance safety and efficiency.

One prevalent type is the manual shut off valve. This valve requires human intervention to open or close the flow. It is simple and reliable but can be a hassle in emergencies. Another common type is the automatic shut off valve. This valve detects pressure changes or leaks. It acts quickly without any human action, making it ideal for critical systems.

There are also solenoid valves. These use electrical signals to operate. Their speed is impressive, but they require a consistent power supply. Lastly, ball valves offer a reliable and durable solution. They provide a tight seal but need proper maintenance to avoid leaks. Each type has its own pros and cons. It's vital to choose the right one for your needs.

Installing and maintaining a gasoline shut off valve involves several key considerations. Firstly, choose an appropriate location for the valve. It should be easily accessible for both regular use and emergency situations. Ensure it is within reach, even in tight spaces. This helps prevent complications during a fuel leak or other emergencies.

Regular maintenance is crucial for safety. Check for leaks or rust periodically. Address any issues immediately. A small leak can lead to major problems. Tips: Keep the area around the valve clean and free from debris. This reduces the risk of damage and improves functionality.

It’s also important to know how to operate the valve correctly. Familiarize yourself with its mechanism. Sometimes, users struggle with opening or closing it efficiently. Practice makes perfect. This way, in an emergency, you won’t waste precious time. Remember, investing time in understanding your shut off valve can save you a lot of trouble later on.

This bar chart represents the flow rate measurements for different sizes of gasoline shut off valves. Higher flow rates denote better performance in terms of gasoline delivery efficiency.

© Copyright 2025 | LittleFirefighter.com | All Rights Reserved | 1EZ Creative: Orange County Web Design

Fusce ut ipsum tincidunt, porta nisl sollicitudin, vulputate nunc. Cras commodo leo ac nunc convallis ets efficitur.

12345 North Main Street,

New York, NY 555555

1.800.555.6789

sale@vibrotools.com