Choosing the right shutoff valve is a crucial aspect of plumbing that can significantly affect the overall performance and safety of your home’s plumbing system. According to a recent report by the International Plumbing Association (IPA), nearly 30% of plumbing failures stem from improper valve selection and installation. This highlights the importance of understanding and selecting the right shutoff valve for your specific needs, whether for residential or commercial applications.

Industry expert Dr. Mark Reynolds, a hydraulics engineer, emphasizes the significance of this choice by stating, "Selecting the appropriate shutoff valve can prevent leaks and water damage, ultimately saving homeowners significant repair costs." With various types of shutoff valves available, including gate, ball, and globe valves, each serves different functions and is optimized for particular applications. Understanding the characteristics and benefits of each valve type can empower homeowners and plumbing professionals alike to make informed decisions that enhance system reliability and efficiency. As we delve deeper into the essential tips for choosing the right shutoff valve, we'll highlight key considerations and best practices that will guide you in making the best choice for your plumbing needs.

Understanding shutoff valves is crucial for effective plumbing management. A shutoff valve serves as a control mechanism to stop or allow the flow of water within a plumbing system. The performance and reliability of plumbing installations often hinge on the type and quality of shutoff valves employed. Several types of shutoff valves exist, each designed for specific functions and applications. Among the most common types are gate valves, ball valves, and globe valves. Gate valves operate by lifting a gate out of the way; they are mostly used when minimal restriction is needed. In contrast, ball valves provide a tight seal and are ideal for situations where a full flow or complete shutdown is necessary.

Another important type is the globe valve, primarily used for regulating flow due to its design, which allows for better throttling. Additionally, there are specialty valves such as stop-and-waste valves, which not only stop the flow but also allow for drainage, making them valuable in outdoor applications. When selecting the right shutoff valve, plumbing professionals must consider factors such as the material compatibility with the water supply, the pressure ratings, and the specific plumbing configuration. Proper understanding of the types and functions of shutoff valves aids in making informed decisions that ensure long-lasting and efficient plumbing systems.

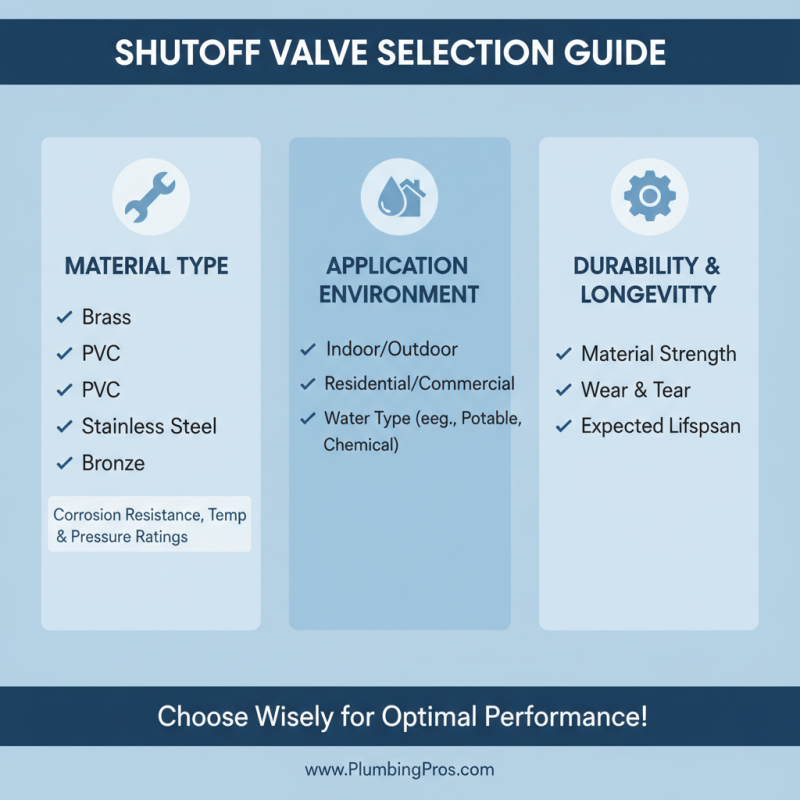

When selecting a shutoff valve for your plumbing needs, several key factors should be carefully considered to ensure optimal performance and longevity. First and foremost, the type of valve material is crucial; options typically include brass, PVC, stainless steel, and bronze. Each material has its strengths and weaknesses depending on the application, such as resistance to corrosion, operating temperature, and pressure levels. Understanding the environment in which the valve will operate will help determine the most suitable material for your specific plumbing system.

Additionally, valve size is another vital aspect to consider. Choosing the right size ensures proper flow and pressure control throughout the plumbing system. It’s important to measure the pipe diameter and consider the flow requirements to prevent issues related to pressure loss or inadequate water supply. Furthermore, the valve's intended use—whether for a main water supply, irrigation system, or appliance—is essential in determining the appropriate shutoff mechanism, such as ball, gate, or globe valves. Each type offers different advantages in terms of ease of use, sealing properties, and maintenance needs, making it imperative to select the one that best aligns with the intended application.

When selecting a shutoff valve for your plumbing system, the importance of sizing and compatibility cannot be overstated. A properly sized valve ensures efficient flow control and helps prevent leaks, which can lead to costly damage. To determine the correct size, you must consider the diameter of the pipe it will connect to, as well as the system’s overall pressure rating. Standardizing the valve size with your plumbing pipes not only ensures optimal functionality but also simplifies installation.

In addition to size, compatibility with your existing plumbing system is crucial. Different plumbing materials—such as copper, PVC, or PEX—require specific types of valves designed to work with them. Using a valve that is compatible with your piping material will enhance the longevity of the system and reduce the risk of corrosion or deterioration.

Furthermore, take into account the connections; whether you need threaded, soldered, or push-fit ends, confirming these details ensures that the valve fits seamlessly into your plumbing infrastructure. By carefully assessing size and compatibility, you can select the right shutoff valve that meets your plumbing needs effectively.

When selecting a shutoff valve for your plumbing system, the choice of material is pivotal, as it directly influences durability, performance, and installation cost. Common materials include brass, PVC, copper, and stainless steel, each with its own set of advantages and disadvantages. Brass is known for its strength and resistance to corrosion, making it ideal for both hot and cold water applications. However, it can be more expensive than other materials. A study from the Plumbing Manufacturers International (PMI) highlights that brass valves consistently outperform in longevity, often lasting up to 20 years with proper maintenance.

PVC valves are lightweight and resistant to chemicals, which makes them a cost-effective option for non-potable water systems. Yet, they might not withstand high pressure and temperatures, limiting their use in certain applications. Copper, highly regarded for its antimicrobial properties, is another solid choice, but its susceptibility to corrosion in acidic water can diminish its effectiveness over time. Meanwhile, stainless steel valves are increasingly favored in commercial applications due to their strength and resistance to oxidative damage.

**Tips:** When choosing a shutoff valve, consider the specific requirements of your plumbing system—pressure ratings and temperature variations are crucial factors. Additionally, ensure compatibility with existing piping materials to prevent future leaks or failures. Regular maintenance checks on valve performance can extend the lifespan of your plumbing system, reducing potential emergency repairs and costs associated with leaks.

| Material | Pros | Cons |

|---|---|---|

| Brass | Durable, corrosion-resistant, good for high-pressure systems | Can be expensive, may corrode in chlorinated water |

| PVC | Lightweight, low-cost, easy to install | Not suitable for hot water, can become brittle over time |

| Stainless Steel | Highly durable, resistance to rust and corrosion | More expensive than other materials, heavy weight |

| Bronze | Resistant to corrosion, good for marine applications | Generally more expensive, can be heavy |

| PP (Polypropylene) | Chemical resistance, lightweight, affordable | Not suitable for high-temperature applications, can degrade under UV light |

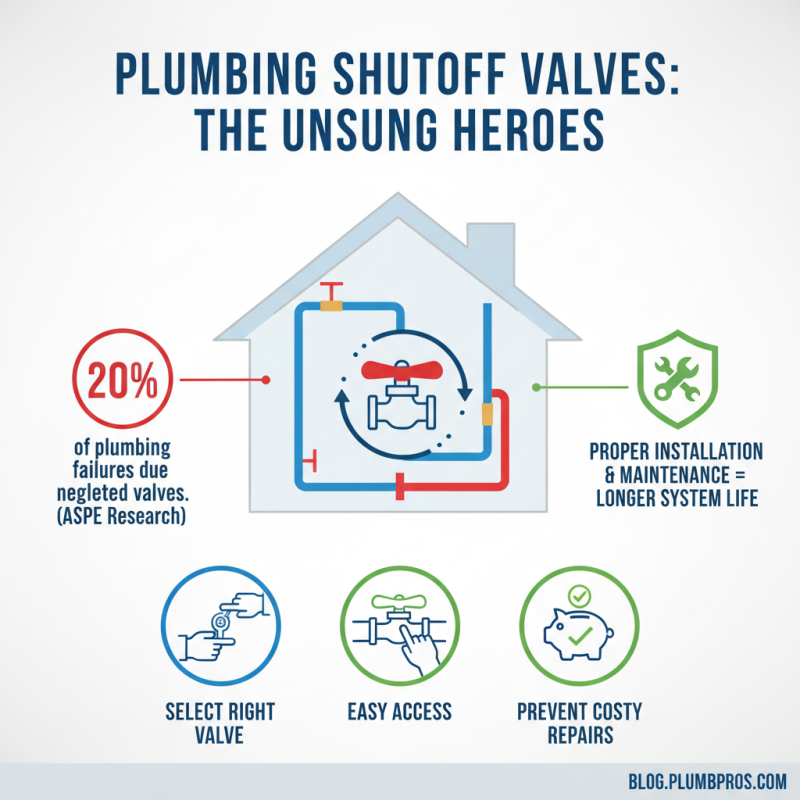

When it comes to plumbing systems, the importance of a proper shutoff valve cannot be overstated, and proper installation and maintenance are key to ensuring long-lasting performance. Research from the American Society of Plumbing Engineers indicates that nearly 20% of plumbing failures can be traced back to neglected valve systems. During installation, it's crucial to select a valve compatible with your piping material and application. Many professionals recommend using a valve that allows for easy access for future maintenance. This proactive measure can prevent costly repairs and increase the longevity of your plumbing system.

Regular maintenance is essential for the performance of shutoff valves. According to the Plumbing Manufacturers International, valves should be exercised once a year to prevent seizing and buildup of mineral deposits. This simple act of opening and closing the valve helps maintain its functionality and ensures that it can operate effectively when needed. Additionally, visual inspections should be conducted for signs of leakage, rust, or corrosion. Addressing these issues promptly can save homeowners considerable expenses in water damage and repairs, ultimately leading to a more dependable plumbing system that meets their needs efficiently.

© Copyright 2025 | LittleFirefighter.com | All Rights Reserved | 1EZ Creative: Orange County Web Design

Fusce ut ipsum tincidunt, porta nisl sollicitudin, vulputate nunc. Cras commodo leo ac nunc convallis ets efficitur.

12345 North Main Street,

New York, NY 555555

1.800.555.6789

sale@vibrotools.com