In the realm of plumbing, the water turn off valve plays a crucial role in managing water flow. John Smith, a seasoned plumbing expert, once stated, "Understanding water turn off valves can save you from costly damages." This insight emphasizes the importance of knowing different valve types.

Many homeowners overlook these vital components. They assume that all valves are the same, which is far from true. Each valve type serves a unique purpose and has distinct features. It's essential to recognize which water turn off valve suits your needs best.

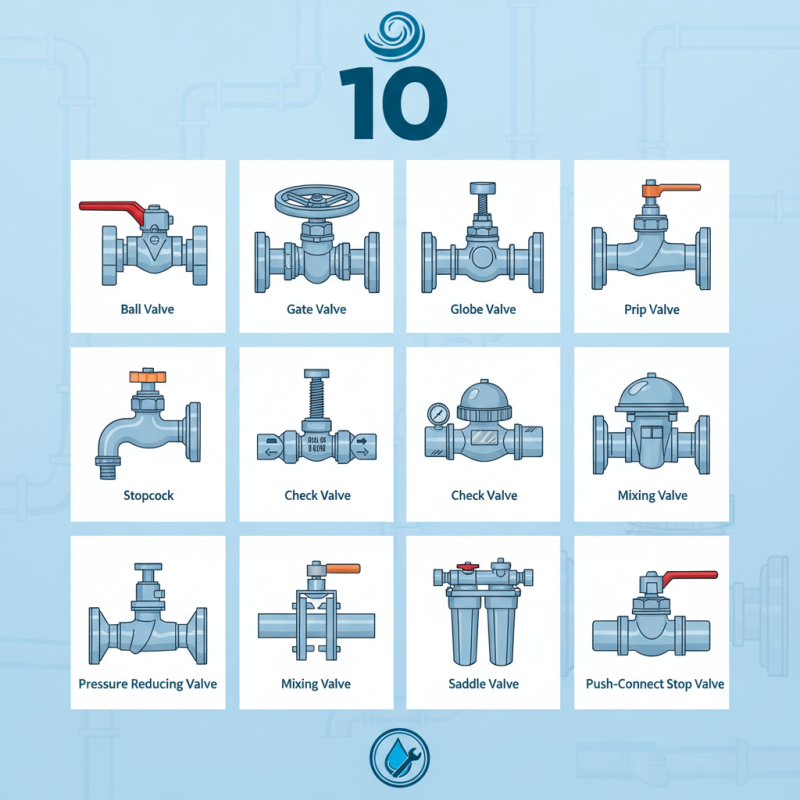

Failing to choose correctly can lead to leaks or bursts. Such incidents can cause significant damage to property. Knowledge of water turn off valves can empower homeowners. This article presents the top 10 types to familiarize you with the options available.

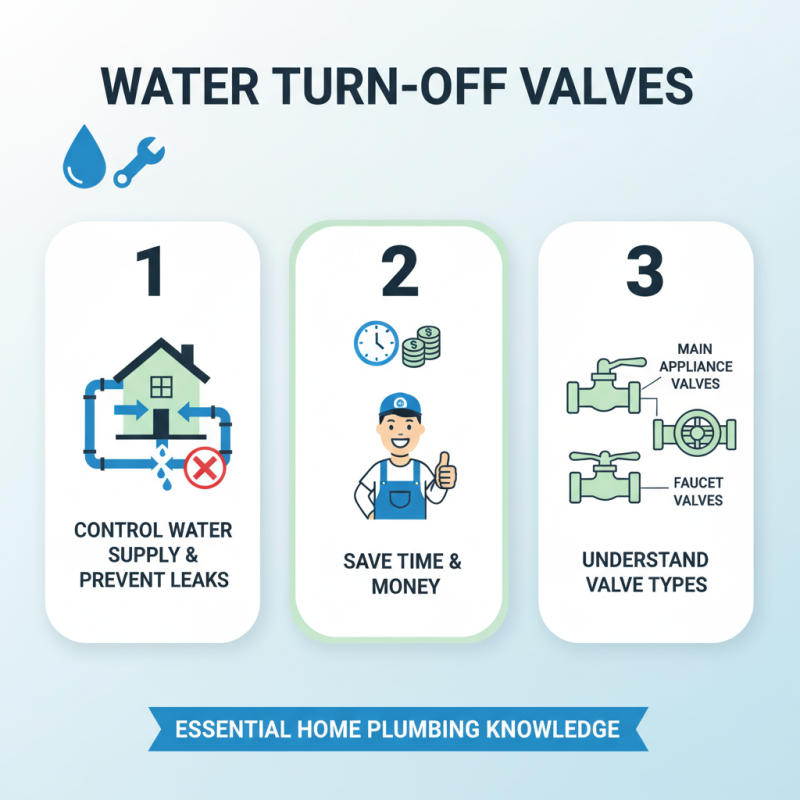

Water turn off valves are essential in managing water flow. They control the supply and help prevent leaks. Understanding these valves can save you time and money.

There are several types of water turn off valves. Ball valves are popular for their durability and ease of use. Gate valves are often found in older structures. However, they may not seal well over time. Other types include globe valves, which regulate flow effectively. Each type has its pros and cons, but the right choice depends on your specific needs.

Knowing how to locate and operate these valves is crucial. If a leak occurs, quick access can minimize damage. Regularly inspect valves for signs of wear. They may need replacement sooner than expected. It’s better to be proactive than reactive. Keeping your plumbing in good shape helps avoid costly repairs later.

When it comes to water turn off valves, understanding their types is essential. Each valve type has unique features and benefits, making them suitable for various applications. For instance, ball valves are widely used due to their durability. They provide a tight seal and can quickly stop water flow. However, adjusting them can sometimes be a struggle, especially in tight spaces.

Gate valves are another common choice. They allow for smooth water flow when fully open. This design is less likely to restrict flow compared to other valve types. Yet, their operation can be slow. This limitation can be annoying in emergencies, where time is critical. Lever-operated valves also offer ease of use. You can quickly turn them off or on with minimal effort.

Some people overlook the significance of valve maintenance. Neglected valves can lead to leaks or system failures. Regular checks can save problems down the road. Each water turn off valve type has its quirks. Choosing the right one requires careful thought and understanding of your specific needs.

When installing water turn off valves, choosing the right type is crucial. Ball valves are popular for their simplicity and durability. They require minimal effort to operate, boasting a quick on-off feature. Installation is straightforward. Make sure to use Teflon tape on the threads to prevent leaks.

Gate valves, on the other hand, can be tricky. They provide a tight seal but are not meant for quick shutoffs. When installing a gate valve, proper alignment is key. Ensure the valve is positioned straight to avoid future leaks. You might need a wrench to tighten connections securely.

Lastly, check valve installation requires extra attention. These valves allow flow only in one direction, preventing backflow. If installed incorrectly, they could fail. Make sure to follow the manufacturer's guidelines carefully. Sometimes, these steps can be easy to overlook, leading to future issues that could easily be avoided. It’s important to pay attention to every detail to ensure a flawless installation.

This chart illustrates the most common types of water turn off valves and their installation techniques, highlighting the ease of installation rated from 1 to 10. The higher the score, the easier it is to install the valve.

Water turn-off valves are essential for managing plumbing systems. To maintain their longevity, regular inspection is crucial. Check for leaks or signs of corrosion. Pay attention to the environment around the valve. Moisture can speed up deterioration.

Cleaning the valve periodically can prevent buildup. Use a soft cloth and mild soap. Do not use harsh chemicals; they can damage the finish. Ensure the valve is operated regularly. Moving it prevents sticking. A valve that is rarely used may become hard to turn.

Consider the placement of your valves. Keeping them accessible can save you time in emergencies. Sometimes, they are hidden or hard to reach. This can lead to neglect. Do not allow that to happen. Proper care goes a long way. Think about these tips on maintenance. They can extend the life of your valves significantly.

| Valve Type | Material | Operation Type | Common Use | Lifespan |

|---|---|---|---|---|

| Ball Valve | Brass, PVC | Manual/Automatic | Water Supply Lines | 10-20 years |

| Gate Valve | Cast Iron, Stainless Steel | Manual | Pipelines | 20-30 years |

| Globe Valve | Brass, Cast Iron | Manual | Flow Regulation | 15-25 years |

| Butterfly Valve | Plastic, Metal | Manual/Automatic | Large Diameter Pipes | 10-15 years |

| Check Valve | Brass, PVC | Automatic | Prevent Backflow | 5-15 years |

| Pressure Relief Valve | Stainless Steel, Plastic | Automatic | Pressure Regulation | 10-20 years |

| Angle Valve | Brass | Manual | Water Supply Lines | 8-15 years |

| PVC Valve | PVC | Manual | Water Distribution Systems | 10-20 years |

| Electric Valve | Stainless Steel, Brass | Automatic | Automated Systems | 10-20 years |

| Foot Valve | Brass, Plastic | Automatic | Pump Suction | 10-15 years |

Water turn off valves are crucial in managing household plumbing. Over time, these valves can wear out, leading to potential leaks or malfunction. Knowing when to replace them can save you from extensive water damage and costly repairs.

Watch for rust or corrosion around the valve. This is usually a bad sign. A valve that feels stiff or doesn't turn smoothly may need replacing. If you notice water stains near the valve, that could indicate leakage. Sometimes, the valve might work but not seal properly, leading to unwanted drips.

Regular inspections can help catch these issues early. Consider checking your valves at least once a year. Keeping an eye on their condition can prevent bigger problems down the road. If you ever have concerns, it's wise to consult with a professional. In plumbing, ignoring small signs can lead to significant issues later.

© Copyright 2025 | LittleFirefighter.com | All Rights Reserved | 1EZ Creative: Orange County Web Design

Fusce ut ipsum tincidunt, porta nisl sollicitudin, vulputate nunc. Cras commodo leo ac nunc convallis ets efficitur.

12345 North Main Street,

New York, NY 555555

1.800.555.6789

sale@vibrotools.com